Weed decarboxylation can be done in different ways. But it's important that you pick the right temperature and duration. In this article we will show you how to activate weed, which settings on the oven you need to use and why decarboxylation is useful.

What is THC?

THC is the "street" abbreviation for delta-9-tetrahydrocannabinol. It is the most familiar substance in weed that has an intoxicating effect. THC makes you high. However, weed plants do not produce THC. Through a complex conversion process, the substance CBGA is converted by enzymes in the plant into both CBDA and THCA. THC is obtained by heating THCA or exposing it to UV light. In other words: you only get high from weed when you heat it.

Decarboxylation

The process of heating weed to convert THCA into THC that makes you high is called decarboxylation. On English websites it is abbreviated to decarb. Heat causes the A to bind to oxygen and it slowly evaporates from the weed in the form of carbon dioxide. THC remains. How fast does that happen? That depends on the temperature. Decarboxylation can actually happen at different temperatures. And there have been misunderstandings about this forever. Which temperature is best for decarboxylation? And for how long?

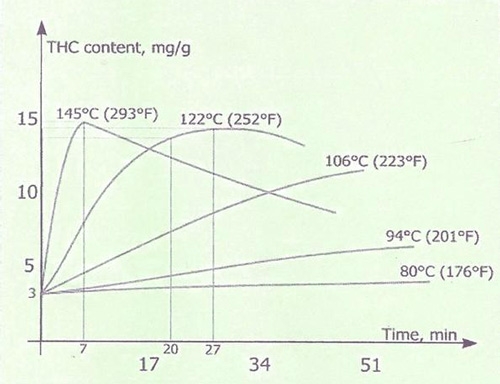

Decarboxylation lesson 1: stop referencing this chart!

The outdated decarboxylation chart above is used, copied and quoted in many forms on the internet. Please do not continue to use this source because:

- This research dates back to 1990 (published in the Journal of Chromatography) [1].

- Cannabinoids were dissolved in hexane; a type of solvent.

- The extract was decarbed on a hot plate.

- There is more recent research with better equipment and with actual plant material.

What Temperature for Decarboxylating Weed?

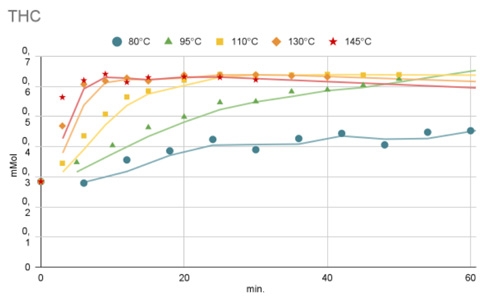

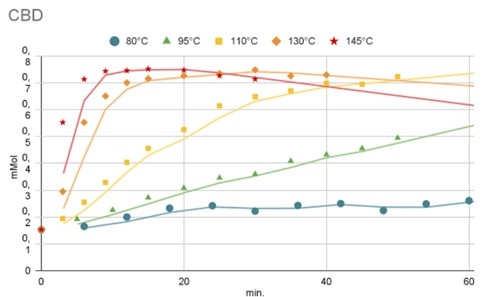

Instead, use the charts below to determine what temperature and time you need for weed decarboxylation. You'll find the explanation below.

How the concentration of THC increases as the result of time and temperature.

How the concentration of CBD increases as the result of time and temperature.

In the charts above, we used the numbers from the 2016 scientific study by Mei Wang's team [2]. The different colours are different temperatures. The higher the line gets, the more THC and CBD was measured in the sample. You can also see that it matters how long the weed is heated at these temperatures. Want to know quickly which temperatures and times work? Here is a handy overview:

- Maximum THC: 30 minutes of decarboxylation at 110° C.

- Both THC and CBD: 20 minutes of decarboxylation at 130° C.

- Maximum CBD: 30 minutes decarboxylation at 130° C.

Decarboxylating Weed in the Oven

Why do we not recommend using 145° C? That would be faster, right? That's right, but ovens don't have an accurate temperature control. The temperature in the oven fluctuates around the set temperature. Your oven often turns on when it's colder than 10 degrees below the set temperature and off when it's 10 degrees warmer than the temperature on the display.

Laying weed on baking paper is also possible, but wrapping it in aluminum foil is better. Then it won't fly through your oven when you turn on the hot air setting.

The placement in the oven is also important. An anecdote. During a test at Dutch-Headshop we put Purple Haze weed for 45 minutes in a small oven. One of those little ovens we bought from a supermarket for less than 50 euros. After half an hour we went to have a look because it started to smell like a fireplace. And yes, the weed was mostly black. Probably because the baking plate was too close to the heating element. In a larger oven you have less trouble with temperature fluctuations, but it is just as possible for your weed to sizzle. Even if you don't set the oven to the crematorium setting. We threw away the carbonized weed. From the brown weed we tried to make weed oil. This weed oil has no noticeable effect; it certainly does not get you high!

Because of our experience and the wide variety of ovens, we recommend you be patient and set the temperature lower. Rather, cook longer and not as hot. Then you avoid burnt tops.

Play it safe: rather set the oven for longer and on less heat.

Weed Decarboxylation in the Oven

Decarboxylating in the oven is an excellent choice. But how do you proceed? Here is a short step-by-step guide:

- Grind your weed. The larger the surface area of contact, the more evenly the weed will be heated.

- Wrap your weed in aluminum foil. Don't fold a ball, but make a sort of large envelope. This will prevent your fine weed from flying away (hot air oven).

- Preheat the oven. Put the weed in the oven only at the right temperature and no longer than the time specified.

- Set the time. 30 minutes at 110° C is enough to get as much THC as possible, without having to worry about burning your weed.

After decarboxylation you take the weed out of the aluminum foil and you can use it for whatever you want.

What to Decarboxylate weed for?

If you are going to smoke, dab or vape weed, decarboxylation is not necessary. This is because this process already happens during consumption because it is heated in these methods. Decarboxylation is necessary when using weed in edibles. Eating weed in other words:

- Spacecake

- Weed gummies

- Cooking with cannabis

- Hash brownies

- Weed oil*

* If you are going to make weed oil, it depends on the method whether you need to decarboxylate or not. Below is an example.

To make space cake and other edibles, we often first make weed butter. This is weed that has been completely dissolved in a fatty substance. This can be cream butter, but vegetable oils and fats such as coconut oil, avocado oil and olive oil will also do just fine. The weed then needs to be decarboxylated before it is dissolved in the butter or oil.

Weed Decarboxylation for THC Oil?

is similar to CBD oil. The only difference is that it gets you super stoned. There are several ways to make weed oil. The most common method is to first soak the weed in consumption alcohol for a while so that the THC and CBD dissolve in the alcohol. Then, the alcohol is slowly evaporated completely before the remaining extract is diluted with a base oil. This process of evaporation is controlled by placing the pan of alcohol in a pan of water, i.e. au bain marie. This prevents the temperature of the alcohol vapour from rising above the boiling point of water. Liquid water cannot get hotter than just under 100 degrees at sea level.

Making weed oil in two pans: au bain marie.

The cannolator method works the same way. But is it necessary to decarboxylate your weed before dissolving it in alcohol? We at the editors disagree on that one. Our argumentation:

The alcohol evaporates between 0.5 to 2 hours at a temperature of 78° C. 78° C is too cold for weed to decarboxylate properly within a day. Just look at the charts above. But, is the opposing view, after the alcohol evaporates, the temperature does rise to the boiling point of water. In the final step of evaporating, you also make sure that the last bit of moisture from the weed and the alcohol evaporates. When the extract is smooth and no longer bubbly, it is time to add oil.

Decarboxylating weed to make weed oil is a good idea, but not necessary. It only makes the weed oil stronger.

Decarboxylating Weed for Weed Oil

Should you decarboxylate weed or not? We put it to the test: the same weed which was not decarboxylated and decarboxylated according to the method above (au bain marie).

The weed we used: Critical Kush from Royal Queen Seeds. Before decarboxylating, we put half of the finely crumbled weed wrapped in aluminum foil for 30 minutes in a large preheated hot air oven at 110° C. It made the whole house smell like weed, so beware if your neighbors don't appreciate that smell. The weed was yellow-brown afterwards and smelled fantastic.

Next, we made weed oil from the unheated weed and the weed from the oven in the same way. The result? From the weed oil from the oven we were stoned with 4-8 drops. From the unheated weed, we needed at least twice the amount for the same effect on the same person.

Conclusion: decarboxylating weed for weed oil is a great idea, but it is not necessary. It only makes the weed oil stronger, but only if the weed is not heated too much.

Buy these pipette bottles to make weed oil here.

Myths Around Weed Decarboxylation

In addition to the first chart we shared with you in this article, there are other misconceptions regarding decarboxylation. Take a look at this list:

- "Curing weed is the same as decarboxylating it". Not true. Curing improves flavour and consistency, but does not or barely converts THCA into THC.

- "Curing weed is necessary to decarboxylate". Not true. Fresh weed can be decarboxylated just fine.

- "When decarboxylating, you lose 30%". Partly true. The loss depends on the method. Too close to the heating element in an oven at too high a temperature and yes: significant loss occurs. Too short and some of the weed remains inactive.

Sources:

- [1] Veress, T. et al. “Determination of cannabinoid acids by high-performance liquid chromatography of their neutral derivatives formed by thermal decarboxylation: I. Study of the decarboxylation process in open reactors”. Journal of Chromatography A 520, pag. 339-347. 9 nov. 1990. DOI: 10.1016/0021-9673(90)85118-F (https://www.sciencedirect.com/science/article/abs/pii/002196739085118F).

- [2] Wang, M. et al. “Decarboxylation Study of Acidic Cannabinoids: A Novel Approach Using Ultra-High-Performance Supercritical Fluid Chromatography/Photodiode Array-Mass Spectrometry”. 1 dec. 2016. PMID: 28861498 DOI: 10.1089/can.2016.0020 (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5549281).